Description

Double component waterproofing coating belongs to solidify waterproof materials, and the Group A is isocyanate terminated pre-polymer polycondensated by polyether and isocyanate, Group B is colored liquid composed of plasticizer, curing agent, thickening agents, coagulant agent and filler, Mix Group A and B evenly as rate and brush on the waterproofing substrate surface, form a elastisic and rubber-like coating film through cross-linking and solidifying at normal temperature , which plays a role of waterproofing.

Double component waterproofing coating forms seamless, integrate elasticity waterproof layer after solidifying, and improve waterproof and seeping resistance of the project, which is waterproof membrane that can not be attained. Especially the coating film has high elasticity and elongation , high adaptability to substrate craking or expansion.

Firm bonding with substrate , coating film has extreme bonding power with concrete, timber, metal, pottery and asbestos shingle, also can be used as bond.

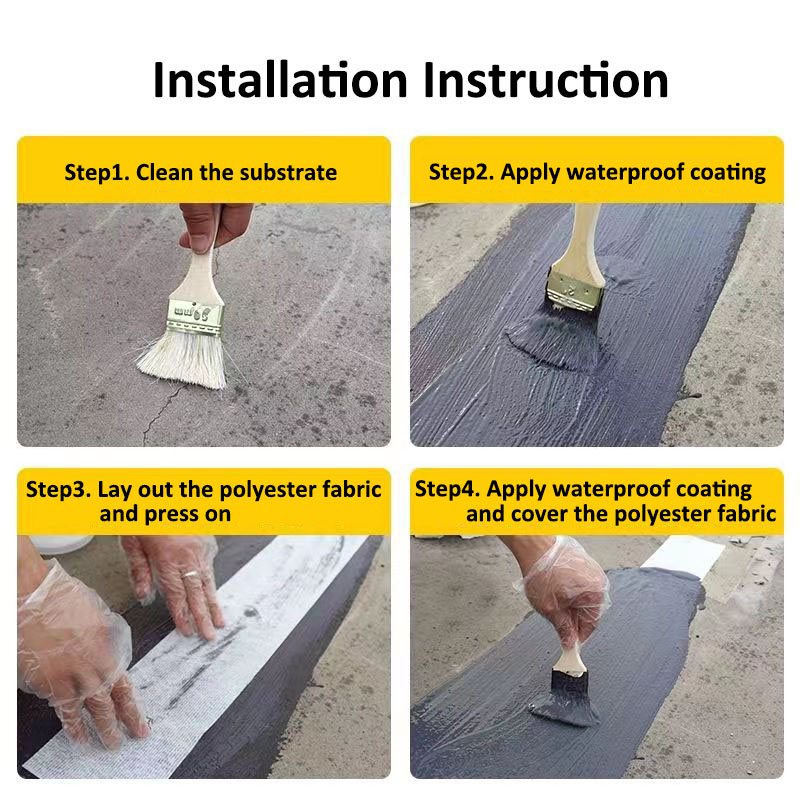

Convenient application ,polyurethane coating film is a cold application waterproof coating ,just mix group A and B as rate when application and brush it on the waterproof substrate .

Easy maintenance ,only maintain the broken parts ,which can reach the original effects of waterproofing ,save time ,save power and low cost .

Environmental product, and reduce the damage to the people and environment..

Reviews

There are no reviews yet.